Deep hole drill services

Turn Key hole making process

RE-sharpening

We provide a re-sharpening service which enables our customers to return their used drills and have them re-ground to factory specifications. By doing so, our customers show cost savings by maximizing the number of regrinds before re-tipping and allowing our expert staff to observe the wear characteristics and make recommendations for improvements in their processes. Standard & Special grinds: N8, N4, N73, N126, facet, chip-breakers, corner & full spherical radius, step grinds, etc. (See catalog page 11)

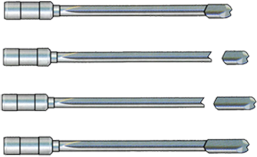

RE-TIPPING

When a tool reaches the point when it can no longer be used because it’s has been re-sharpened to its limit, it’s chipped, or misused, etc., it can be sent back for re-tipping. Once a tool is re-tipped it performs exactly as a new tool. This process extends cost savings to our customers as much as 20% of the cost of a new tool.

This service can be performed on all competitor’s tools.

RE-STRAIGHTENING

One of the most critical features of the tools performance is it’s straightness from the driver to the tip. Throughout the life of a tool it’s subjected to numerous removals from the machine, re-sharpening, re-installations, crashes, miss-handling, etc. These scenarios will contribute to inconsistency in hole -size, excessive run-out and premature tool wear. Most times as long as a tool isn’t kinked, it can be re-straightened at a fraction of the cost of a new tool.

This service can be performed on all competitor’s tools.

single flute

gundrills