SHARPENING FIXTURES & PACKAGES

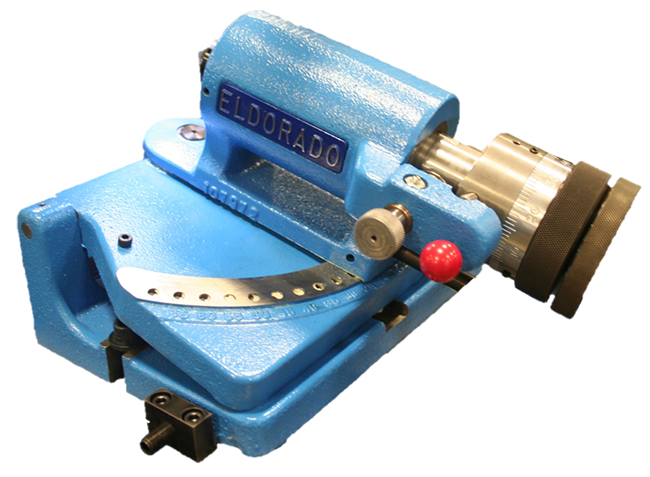

Drill Masters Eldorado Tool Model “B” Sharpening Fixture (Part# 107245)

The model “B’ gundrill sharpening fixture is the most widely used gundrill sharpening fixture in the world. The “B” fixture is used to sharpen gundrills from .055″ (1.39mm) to 1.062″ (26.9mm) in diameter. It mounts easily on conventional tool and cutter or surface grinders. Any shop personnel can quickly and accurately reproduce the required nose geometry without carbide and diamond wheel waste. This unit is available as stock items and come with detailed operation instructions.

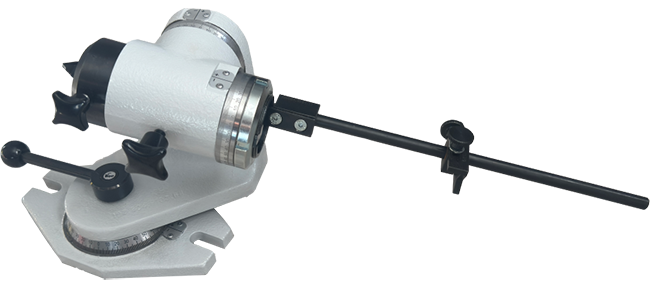

Universal Clamping Device – Facet Grind Fixture (DMFG-1)

- Gundrill Capacity: 0.039 – 1.575” (1.0 – 40.0mm)

- Precise grind angle repeatability

- Magnification microscope recommended for drill sizes less than 0.100”

Complete Custom Gundrill Sharpening System

- Drill capacity of 0.075” – 1.0625” (1.91mm – 26.99mm)

- X-axis & Y-axis slides, head adjustable Z-axis

- Digital readout for X and Y axis

- Diamond cup grinding wheel

- Dust collection system

- Video inspection microscope with LED monitor up to 40:1 magnification

DME Tool M1 Gundrill Sharpening System

We have a dedicated staff of experts with over 85 years of combined experience to assist the customer with all of their special requirements. At the beginning phase of an engineering project, give us a call to discuss the process sequences required to avoid unnecessary problems in the future. If the customer is experiencing any gundrilling problems or has questions, they should contact our engineering staff for solutions.

TECH SUPPORT

We have a dedicated staff of experts with over 85 years of combined experience to assist the customer with all of their special requirements. At the beginning phase of an engineering project, give us a call to discuss the process sequences required to avoid unnecessary problems in the future. If the customer is experiencing any gundrilling problems or has questions, they should contact our engineering staff for solutions.