INDUSTRY STANDARD NOSE GRINDS

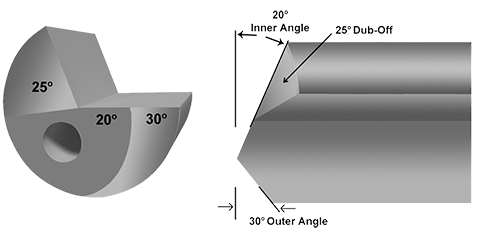

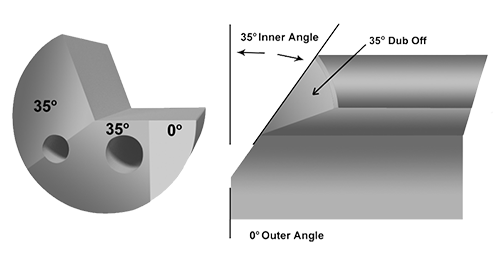

N8

General purpose stock drill grind for steel, inconel and stainless steel are most often used with stock ‘R1′ O.D. contour. This geometry can be reproduced on our Model “B” Sharpening Fixture.

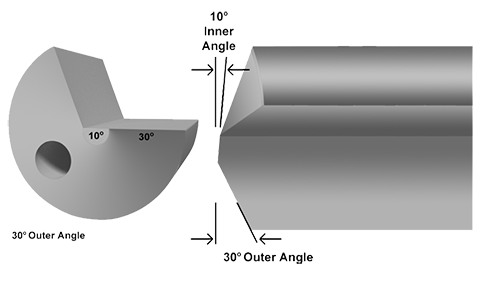

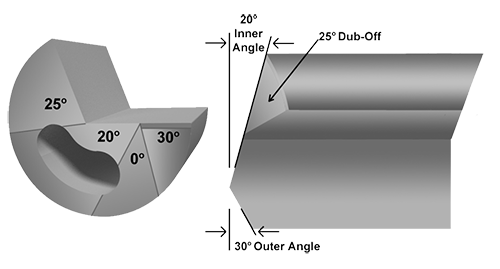

N4

In aluminum and brass, use this grind with ‘R4′ O.D. contour for best hole finish.

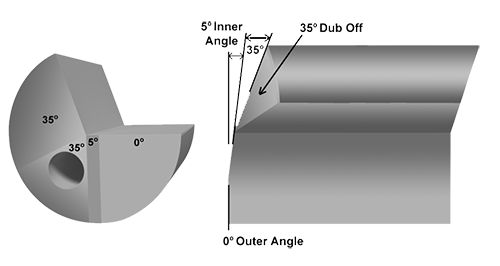

N73

This Nose Grind is used for drilling stacked parts and angular entries. Due to the point’s placement near the center of the drill, this is the strongest gundrill.

N126

This Nose Grind is for applications requiring nearly flat bottoms. It can also be ground for a completely flat bottom or on difficult materials used to qualify bottoms only.

Copper

This Nose Grind is for applications requiring nearly flat bottoms. It can also be ground for a completely flat bottom or on difficult materials used to qualify bottoms only.

Facet F-8

Facet grinds are preferred on specific applications or when regrind fixtures limit the cam type sharpenings. They can be ground to various slash type angles with good performance, and they allow a greater amount of clearance for coolant to cool the chip at the cutting edge. This grind is standard on most European applications.

TECH SUPPORT

We have a dedicated staff of experts with over 85 years of combined experience to assist the customer with all of their special requirements. At the beginning phase of an engineering project, give us a call to discuss the process sequences required to avoid unnecessary problems in the future. If the customer is experiencing any gundrilling problems or has questions, they should contact our engineering staff for solutions.