Related Products & Accessories

Re-Sharpening Diamond Wheels

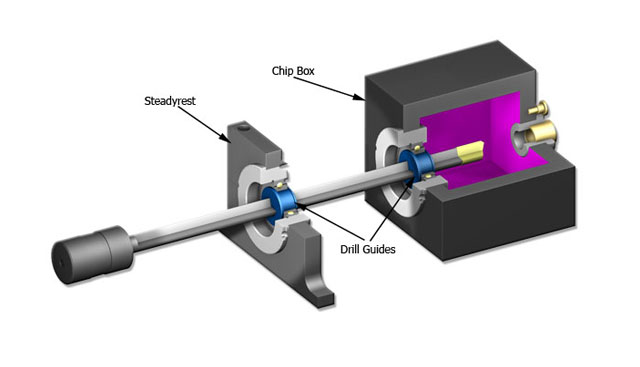

DRILL Guides

Drill guides of molded vinyl provide relief from whipping and bowing for higher speeds with less vibration. Sizes run from 0.070” (1.778mm) to 2.18” (55.372mm).

Flexible plastic Drill Guide bushings stop drill whipping and seal the chip box by stretching over the carbide drill tip and contracting onto the steel drill body. They are typically mounted in a bearing and rotate with the drill. This is our first and oldest product and is still used by many customers to maximize penetration rates, accuracy, and stop vibration. These bushings perform the same function as our SnapGuide®. Our signature Blue Bushings® guarantee you top quality.

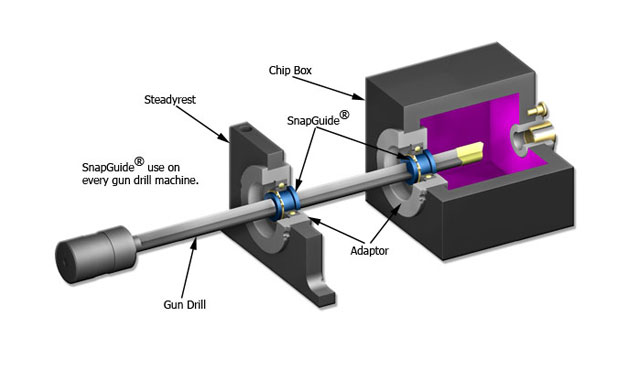

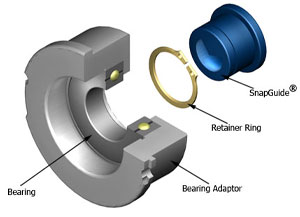

Snap Guides

Chip Box

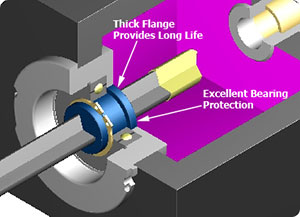

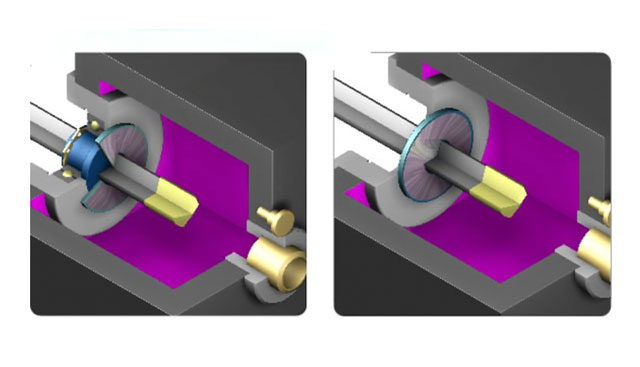

Flexible plastic SnapGuide® bushings stretch over carbide gun drill tip and contract over steel tube to stop drill whipping and vibration. Contoured hole in SnapGuide® forms perfect seal on gun drill. Our signature Blue Bushings® always guarantee

you top quality.

Chip Box

Flexible plastic SnapGuide® bushings stretch over carbide gun drill tip and contract over steel tube to stop drill whipping and vibration. Contoured hole in SnapGuide® forms perfect seal on gun drill. Our signature Blue Bushings® always guarantee

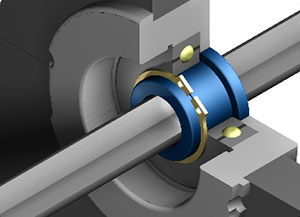

you top quality.  Steadyrest

SnapGuide® with round holes are used in the steadyrest. This speeds drill loading by eliminating the need to orient the contoured hole in the SnapGuide® with the drill. Extra clearance in SnapGuide® allows drill tip to slide through easier. Also helps prevent steadyrest from being dragged out of position.

Steadyrest

SnapGuide® with round holes are used in the steadyrest. This speeds drill loading by eliminating the need to orient the contoured hole in the SnapGuide® with the drill. Extra clearance in SnapGuide® allows drill tip to slide through easier. Also helps prevent steadyrest from being dragged out of position.

Set Up Reduction

Each bearing holder has large drill range capacity reducing or eliminating holder change-overs on machine.

SnapGuide® Drill Range

17mm OD – <=.0769 -.5099

20mm OD – <=.0831 -.6399

30mm OD – .0985 – 1.0449

45mm OD – .800-1.5199

75mm OD – 1.520-2.044+

Chip Deflectors

Chip deflectors made of polypropylene in sizes, 078” (1.98mm) to 2.000” (50.8mm) keep oil and chips in the chip box.

Chip Deflectors stop metal chips and cutting oil from exiting the back of the chip box. They provide sealing only and no drill support. They are used on gun drill machines on short rigid drills when whipping is not a problem. They are also used in front of a Drill Guide or a SnapGuide® to extend bushing and bearing life. Chip Deflectors feature a hardened steel face bonded to a flexible polymer backing to provide perfect sealing on the drill and long life.

Collets

Collets are designed to work in conjunction with the Eldorado model “B” sharpening fixture. Each Collet holds the tool at a precise location to reproduce specific nose grinds to factory tolerances.

Collet Inserts for Eldorado Model “B” Gundrill Sharpening Fixtures Gundrill Sizes .0750 – .7500.

Filter Bags

Canister Filters

Gundrill Bushings

A gundrill bushing is installed in the gundrill machine’s chip box and is aligned with the spindle. It is used for diameters over .7500″ (19.05mm) replacing the GDI and GDL to support the tool into the material providing sufficient rigidity to prevent the carbide tip from chipping.

Gundrill Insterts (GDI)

A gundrill insert is required on all conventional gundrill machines from .0550″ (1.397mm) through .7500″ (19.05mm) and the tolerance is + .0002″ (.0051mm) and – 0. It is used to guide the tool into the material providing sufficient rigidity to prevent the carbide tip from chipping and to insure consistent run-out from hole to hole. The insert is replaced once it becomes oversized do to usual wear or from tool breakage. It is recommended that the drill bushing is replaced once it is 0.0005″ over the drill size otherwise inconsistent drift or tool chipping may occur.

Gundrill Liners (GDL)

A gundrill liner is installed in the gundrill machine’s chip box and is aligned with the spindle. The specified size GDI is inserted into the GDL and allows for precise accuracy for the tool to enter the material.

TECH SUPPORT

We have a dedicated staff of experts with over 85 years of combined experience to assist the customer with all of their special requirements. At the beginning phase of an engineering project, give us a call to discuss the process sequences required to avoid unnecessary problems in the future. If the customer is experiencing any gundrilling problems or has questions, they should contact our engineering staff for solutions.